Introduction: From all-night operations to intelligent control - disruptive changes in cleaning technology

At three o'clock in the morning, workers at a food factory in the Midwest of the United States were still manually dismantling pipes and moving equipment, and the noise of high-pressure water guns cut through the night sky - this is the norm in traditional food factories. However, in a modern dairy factory in California, the factory manager only needs to tap the tablet computer, and the CIP (cleaning in place) system will automatically start: the cleaning liquid circulates accurately, and the production line resumes operation after 40 minutes, and fresh dairy products continue to flow to supermarket shelves.

This quiet revolution stems from the popularization of CIP automated cleaning technology. Today, environmentally friendly CIP systems with low water consumption and low chemical agents have become the new industry standard. Data shows that production lines using intelligent CIP systems can reduce annual downtime by 700-800 hours (about 30 days), and significantly improve efficiency.

The core advantages of CIP system: high efficiency, precision and sustainability

1. Triple cleaning technology: leaving no place for stains to hide

Mechanical flushing force: The high-pressure pump drives the fluid to form turbulence at a speed of 2-5m/s (3 times faster than traditional methods) to thoroughly flush the inner wall of the pipe.

Chemical decomposition force: Intelligently adjust the formula of the cleaning agent, such as 75℃ sodium hydroxide to decompose protein residues, and nitric acid solution to dissolve mineral crystals.

Thermodynamic activation: Precise temperature control to 85℃±2℃ increases the activity of the cleaning agent by 400%, and the cleaning effect is more thorough.

2. Seven-step standardized process: a leap from experience to data

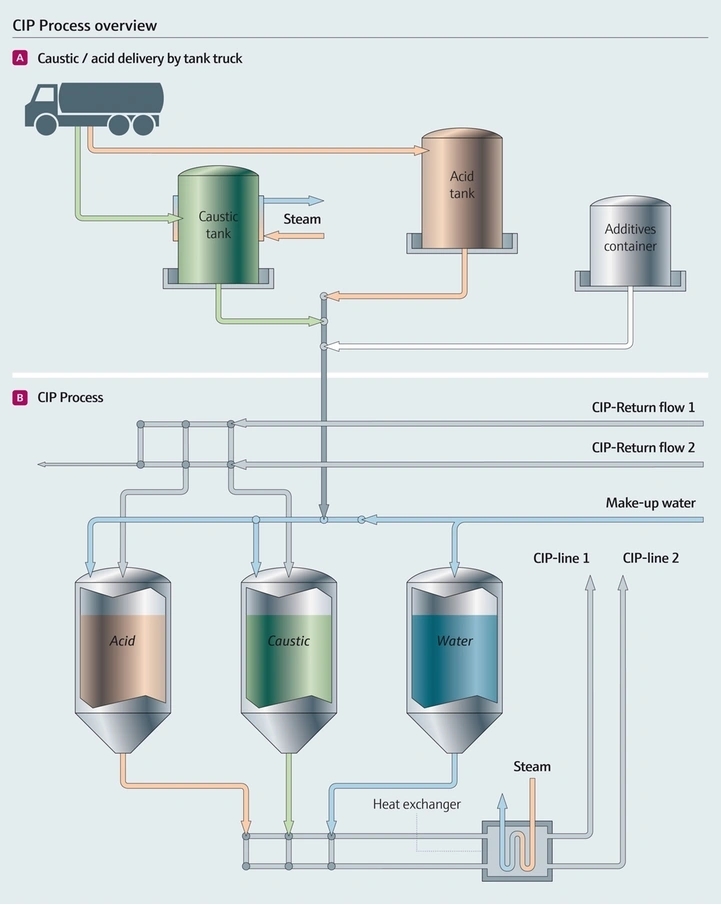

The CIP system is controlled by PLC and decomposes cleaning into 7 stages:

Pre-rinse → alkali wash → acid neutralization → hot water rinse → disinfection → pure water final rinse → drying

Each step is monitored in real time by sensors to ensure compliance and consistency.

3. Three major business values

Efficiency improvement of 50%: A dairy company reduced its annual downtime by 700 hours and increased its production capacity by 15%.

Water saving 40%-60%: Closed-loop technology allows a beverage factory to save 5,000 tons of water per year.

Global compliance: Real-time data recording meets FDA, HACCP and other standards, helping companies quickly pass international certification.

Diverse application scenarios of CIP systems

Tank cleaning: Intelligent regulation of temperature and pressure

Support hot cleaning (high temperature sterilization) or cold cleaning (energy-saving mode), dynamically adjust pressure to avoid equipment damage.

Customized equipment cleaning

Provide exclusive cleaning programs for different equipment (such as filling machines, mixers), and flexibly adapt to production needs.

Residue management

Determine the best cleaning agent (alkali/acid) through chemical analysis, optimize concentration and temperature, and avoid cross contamination.

Future trends: Three major evolutionary directions of CIP systems

AI-driven predictive maintenance

IoT sensors monitor pollutants in real time, and AI automatically adjusts cleaning parameters, saving 22% of consumables; predict pump and valve failures, reducing 70% of downtime risks.

Green cleaning technology

Low-temperature enzyme cleaning agent + ozone disinfection solution, wastewater treatment costs are reduced by 60%, in line with the US "dual carbon" policy, and can receive a subsidy of up to $500,000.

Modular design

The pump group and control module are "plug and play", the transformation cycle is shortened from 3 months to several weeks, the initial investment is reduced by 40%, and the maintenance cost is reduced by 60%.

Conclusion: Smart cleaning, empowering a sustainable future

When traditional factories still rely on manpower to clean overnight, the CIP system has reconstructed the production process through data and algorithms. It is not only a technological upgrade, but also a revolution in management thinking - using less water, lower energy consumption, and higher efficiency to create long-term value for the company.

Are you ready to join this cleaning revolution?