Introduction: Why has hospital sewage treatment become the focus of environmental protection supervision?

"A large hospital in the United States was fined $1.2 million by the environmental protection department because of excessive ammonia nitrogen in the sewage treatment system" - this kind of news is no longer rare in the United States. With the strict implementation of the Clean Water Act and state environmental protection regulations, the problem of excessive ammonia nitrogen in hospital sewage is becoming the focus of environmental protection inspections. According to statistics, about 60% of hospital sewage treatment systems in the United States have insufficient ammonia nitrogen treatment capacity. Excessive discharge may not only lead to high fines, but also affect the hospital's rating and social reputation.

Why do hospital sewage treatment systems frequently "light up red lights" on ammonia nitrogen indicators? Is it a technical problem or a management loophole? This article will analyze the reasons in depth and provide practical solutions.

1. Six main reasons for excessive ammonia nitrogen in hospital sewage

(1). Excessive ammonia nitrogen load in raw water: Failure to control pollution at the source

The sewage composition of American hospitals is complex, especially ward urine (urea concentration can reach 1500-3000 mg/L), operating room flushing wastewater (containing protein decomposition products) and laboratory chemical wastewater, which may bring high concentrations of ammonia nitrogen. If pretreatment is not in place, these pollutants will easily cause excessive ammonia nitrogen after entering the biochemical treatment system.

(2). Nitrifying bacteria activity is affected: the key role of temperature and pH value

Nitrifying bacteria are the core microorganisms for ammonia nitrogen degradation, but they are very sensitive to the environment:

Low temperature effect: When the water temperature is below 10℃ in winter, the activity of nitrifying bacteria decreases significantly, which may cause the ammonia nitrogen concentration in the effluent to soar.

pH fluctuation: When pH<7.0, the efficiency of nitrification reaction is significantly reduced, and the acid produced by the denitrification process will further inhibit nitrifying bacteria.

Insufficient dissolved oxygen: If the aeration system fails and causes DO (dissolved oxygen) <2.0 mg/L, nitrifying bacteria will enter a "dormant state".

(3). Improper sludge management: Excessive sludge discharge leads to bacterial loss

A newly built hospital once exceeded the ammonia nitrogen standard due to excessive sludge discharge - the sludge concentration (MLSS) dropped sharply from 4000 mg/L to 2000 mg/L, and the loss of nitrifying bacteria exceeded 60%. Studies have shown that the sludge age (SRT) needs to be >15 days to maintain the stability of nitrifying bacteria. Frequent sludge discharge or insufficient reflux will cause the bacterial community to fail to reproduce normally.

(4). Process design defects: insufficient hydraulic retention time

The hydraulic retention time (HRT) of the traditional activated sludge method is usually only 4-6 hours, while complete nitrification requires 8-12 hours.

Wrong process selection: In hospitals that only use contact oxidation technology, the ammonia nitrogen removal rate is generally less than 60%, while the simultaneous nitrification and denitrification (SND) process can be increased to more than 85%.

Weak impact resistance: The sewage volume of a hospital surged by 50% due to the epidemic, and the regulating tank could not buffer it, and the system eventually collapsed.

(5). Sudden water quality fluctuations: unforeseen pollution events

Dumping of laboratory waste liquid, excessive use of disinfectants, and overflow of pipe networks caused by heavy rain may cause the inlet ammonia nitrogen concentration to exceed 100 mg/L instantly. A hospital was once paralyzed for several weeks because the cleaner mistakenly discharged ammonia-containing wastewater.

(6). Equipment aging: Decreased efficiency of aeration system

Problems such as blockage of aeration heads, reduced fan efficiency, and pipeline corrosion may cause the actual oxygen supply to decrease by 30%-50%. A hospital has not replaced the aerator for 5 years, and the DO value has been lower than 2.0 mg/L for a long time, and the ammonia nitrogen eventually exceeded the standard by 3 times.

2. Solution: From passive response to precise prevention and control

(1). Front-end control: Reduce ammonia nitrogen load

Classify and collect high ammonia nitrogen wastewater (such as nephrology department and obstetric ward), and use MAP (magnesium ammonium phosphate) crystallization method for pretreatment, which can reduce the ammonia nitrogen load by more than 50%.

Dynamically adjust the inlet water: install an online ammonia nitrogen monitor, and automatically start emergency diversion when the concentration is >80 mg/L.

Strengthen physical and chemical pretreatment: add flotation + activated carbon adsorption units to intercept sudden high-concentration ammonia nitrogen.

(2). Mid-end optimization: improve the activity of nitrifying bacteria

Insulation measures: carry out insulation transformation of the biochemical pool (such as underground design + steam heating) to ensure that the water temperature is >12℃.

Intelligent pH control: automatically add sodium carbonate to maintain the optimal pH range of 7.5-8.0.

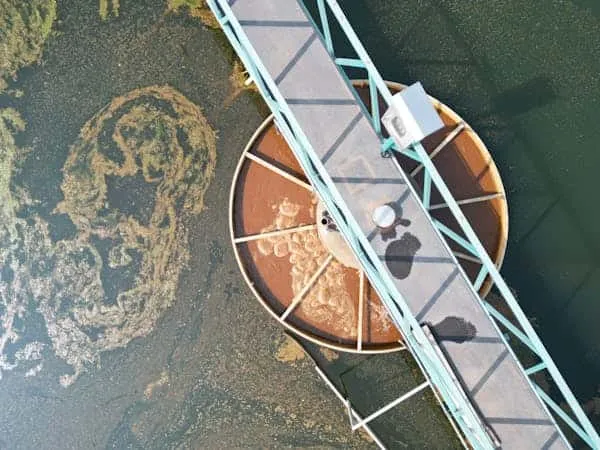

Precise aeration: upgrade magnetic suspension fan + microporous aeration disk to ensure that DO is stable at 3.0-4.0 mg/L.

(3). Back-end upgrade: adopt efficient treatment technology

MBR membrane method: intercept nitrifying bacteria through 0.1μm ultrafiltration membrane, extend sludge age to 30 days, and ammonia nitrogen removal rate >95%.

Two-stage A/O process: anaerobic ammonia oxidation (ANAMMOX) is used in the front stage to directly convert ammonia nitrogen, and denitrification is used in the back stage for deep denitrification.

Smart water system: Use AI algorithms to predict water quality fluctuations, dynamically adjust operating parameters, and improve shock resistance by 80%.

(4). Long-term operation and maintenance: From manual management to digital management

Sludge health monitoring: Weekly testing of SVI (sludge index) and SOUR (specific oxygen consumption rate), and establishment of a bacterial activity early warning model.

Equipment preventive maintenance: Regular inspection of key equipment such as aeration systems and return pumps to reduce the failure rate by 60%.

Emergency treatment plan: Equip the outlet with chlorine dioxide or breakpoint chlorination devices to ensure rapid processing when sudden exceeding the standard.

3. Actual combat case: Successful transformation of a hospital in the United States

In 2021, a large hospital in the Midwest of the United States increased its sewage volume due to expansion, and ammonia nitrogen exceeded the standard for a long time to 30 mg/L (standard 15 mg/L). Through the following transformation:

Pretreatment upgrade: Add a urease decomposition tank, and the ammonia nitrogen in the raw water is reduced from 120 mg/L to 60 mg/L.

Process improvement: Change the traditional activated sludge method to MBBR (moving bed biofilm) + MBR combined process.

Intelligent management and control: Deploy IoT sensors + cloud platform remote monitoring.

After the transformation, the effluent ammonia nitrogen is stable below 5 mg/L, saving $400,000 in annual pharmaceutical costs, and becoming a state environmental protection demonstration project.

Conclusion: The future direction of hospital sewage treatment

Hospital sewage treatment is not only an environmental compliance issue, but also the key to the sustainable development of hospitals. To solve the problem of excessive ammonia nitrogen, it is necessary to start from source control, process optimization, and intelligent management. In the future, with the popularization of IoT and AI technology, hospital sewage treatment will be more efficient and reliable, helping hospitals avoid fines, improve ratings, and protect the environment.